Homogeneous

Catalysis

We are

studying catalysts which will give very high selectivity to

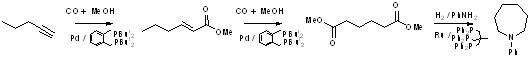

desirable products often via cascade reactions. In Scheme 1,

α,ω-diesters are formed in a single cascade reaction by the

methoxycarbonylation of alkynes. The same catalyst catalyses the

methoxy-carbonylation to the α, Β-unsaturated ester (the reaction can

be stopped here), the double bond isomerisation and the second

methoxycarbonyation, which only occurs when the double bond is in the

least thermodynamically favoured terminal position.1

Scheme 1. Formation of dimethyl adipate

from 1- butyne by a

methoxycarbonylation - isomerisation - isomerisation Cascade sequence;

also shown is the reductive amination of dimethyl adipate to

N-phenylazacycloheptane

In a

separate reaction, also shown in Scheme 1, α,ω-diesters can be

converted by reductive amination to heterocycles. Related reactions are

the formation of long chain α,ω-diesters from natural feedstocks

(Scheme 2)2

and the catalytic hydrogenation of amides to amines (Scheme

3).3

Scheme 2. Upgrading of methyl oleate to a

polymer precursor

|

Scheme 3. Hydrogenation of amides to amines

|

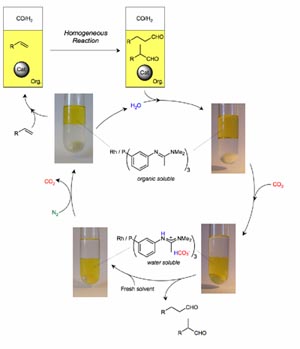

In

addition, we have a major programme on new approaches to separating

products from the catalyst in homogeneous reactions using biphasic

systems involving aqueous, ionic liquid and supercritical fluid

solvents. Recent studies have included additives to aqueous biphasic

systems which give rate enhancements of 100 times without catalyst

leaching or emulsion formation, catalysts which can be switched between

water and organic phases by bubbling or removing CO2 (Figure

1) and supported ionic liquid phase catalysts with supercritical flow.4

Figure 1.

Catalyst separation by transfer

into and from water using CO2

|

|

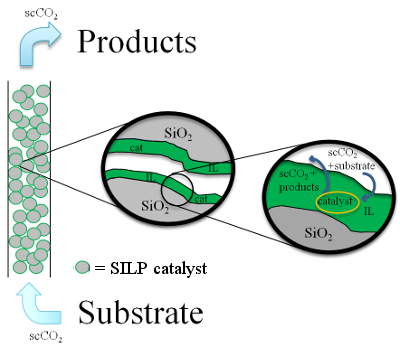

Supported

ionic liquid phase catalysts are composed of a thin layer of ionic

liquid adsorbed onto the support pores, being the catalyst dissolved in

the ionic liquid. This type of catalyst has been used to perform

different reactions in a continuous flow mode with supercritical CO 2

as

carrier gas. The substrates, fed continuously, are dissolved into the

supercritical CO 2

and diffused into the ionic liquid layer to react with the catalyst and

the products being also removed by the stream of

supercritical CO 2. The ionic liquid is

insoluble in CO 2 avoiding leaching of

it and the catalyst (Figure 2).

Figure 2. Squeme of continuous flow

SILP catalysis

This system has been succesfully applied to different reactions as

metathesis, hydrogenations and carbonylations. 5

References:

- A. A. N. Magro, L. Robb, P. J. Pogorzelec, A.

M. Z.

Slawin, G. R. Eastman and D. J. Cole-Hamilton,

2010,

1(6),

723-730.

- C.

Jimenez-Rodriguez, Graham R. Eastham and D. J. Cole-Hamilton, Inorg. Chem. Commun.,

2005, 8, 878-881.

- A. A. Núñez Magro, G. R. Eastham and D. J.

Cole-Hamilton,

Chem.

Commun,

2007, 3154-6.

- S. L. Desset and D. J. Cole-Hamilton,

Angew.

Chem.

Int. Ed., 2009, 48,

1472-1474.

- R.

Duque, E. Ochsner, H. Clavier, F. Caijo, S. P. Nolan, M. Mauduit and D.

J. Cole-Hamilton, Green

Chem.,

2011, 13, 1187-1195.

|